Foundation of Precision

Precede Precision Engineering was founded, with focus in high precision tooling project

Delivering high-precision tooling, engineering, and advanced injection molding solutions for global technology-driven industries.

Established in 1993, Precede Group has been at the forefront of high-precision tooling and engineering and has grown into a leading manufacturer for precision injection molding in Malaysia’s semiconductor industry since 2005. Over the years, we have expanded our capabilities to include:

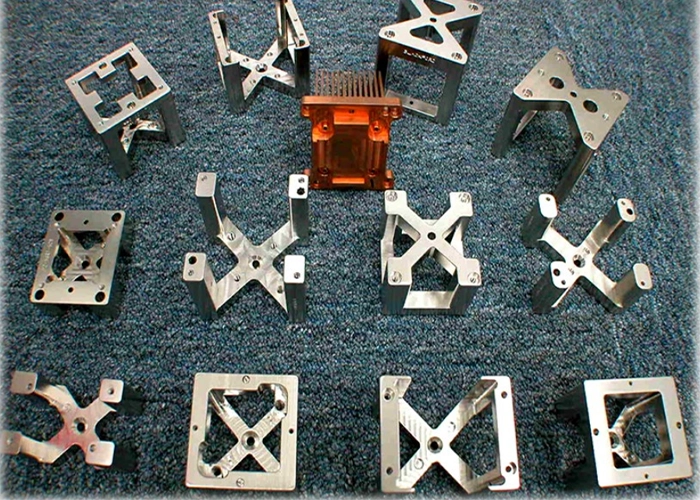

🔹 Precision Tooling

🔹 Components

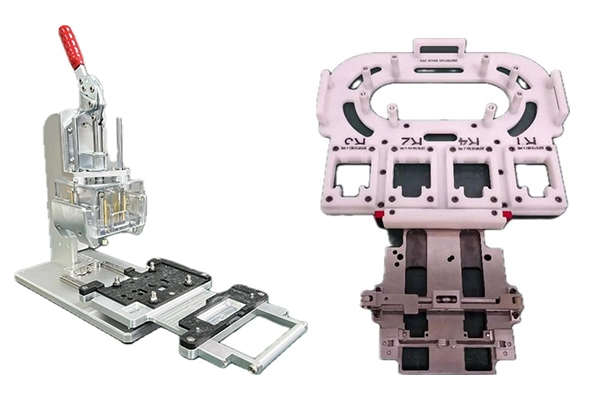

🔹 Jig & Fixture

🔹 Injection Molding

🔹 Assembly services include High Level Assemblies (HLA)

Certified with ISO 9001:2015, UL, and RoHS certifications, we ensure globally compliant, high-quality solutions tailored to your precision manufacturing needs.

Precede Group is a trusted precision engineering partner, delivering excellence in high precision tooling and injection molding since 1993. With a foundation rooted in the semiconductor industry, we have expanded our expertise to serve a diverse range of sectors, offering tailored solutions through continuous innovation and commitment to quality.

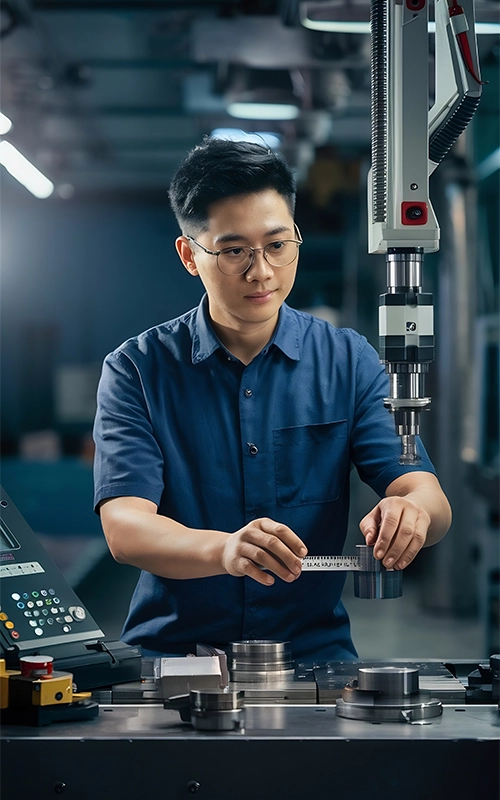

We take pride in being a one-stop centre for precision tooling, mold fabrication, and automation projects — driven by a dedicated team and advanced manufacturing technology. Our evolution reflects our ability to adapt to market needs while maintaining a focus on quality and performance.

From a single-focus tooling company to a trusted precision manufacturing partner, our journey is defined by innovation, dedication, and continuous growth.

Precede Precision Engineering was founded, with focus in high precision tooling project

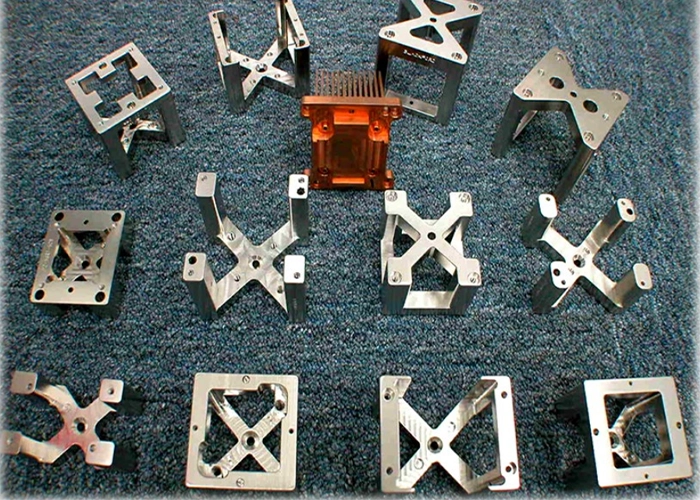

We expanded our capabilities by forming a dedicated jig and fixture team, enabling us to offer comprehensive mechanical support for complex manufacturing needs.

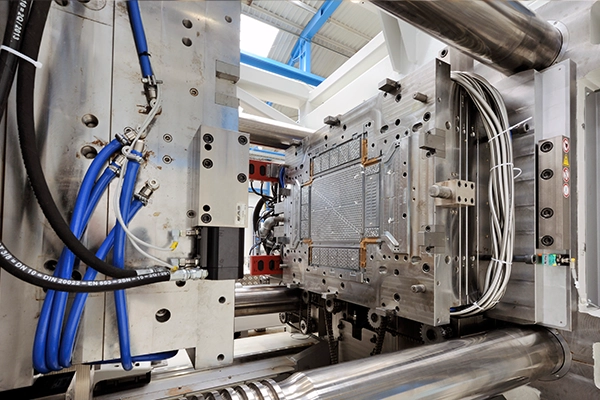

With increased demand, we incorporated Precede Precision Molding to offer end-to-end plastic injection molding solutions under one roof.

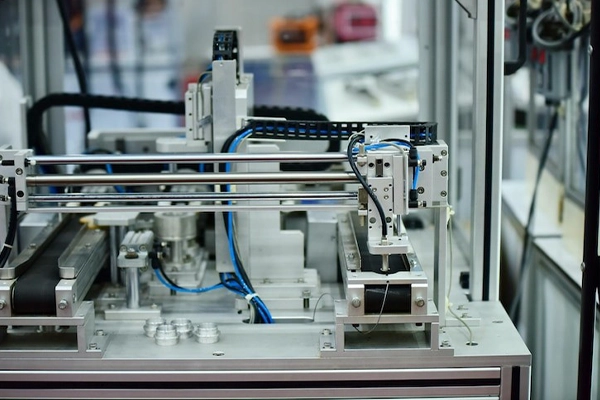

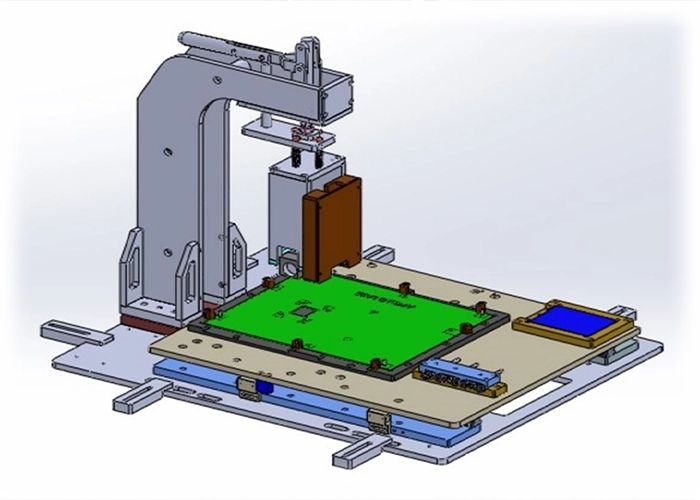

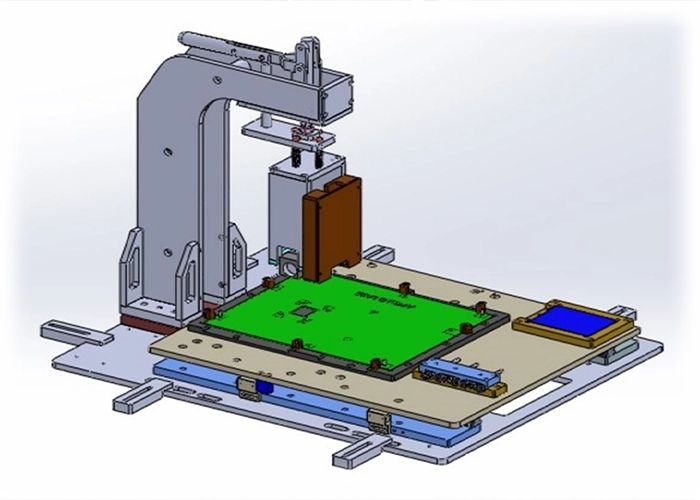

To stay ahead of industry trends, we ventured into automation projects, enhancing efficiency and precision across our production lines.

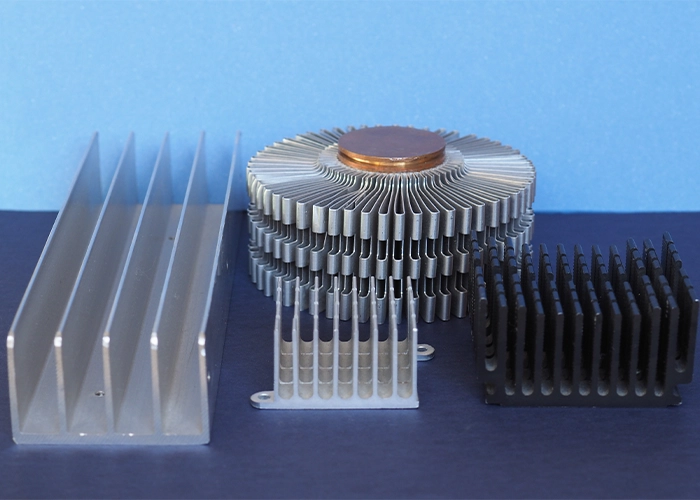

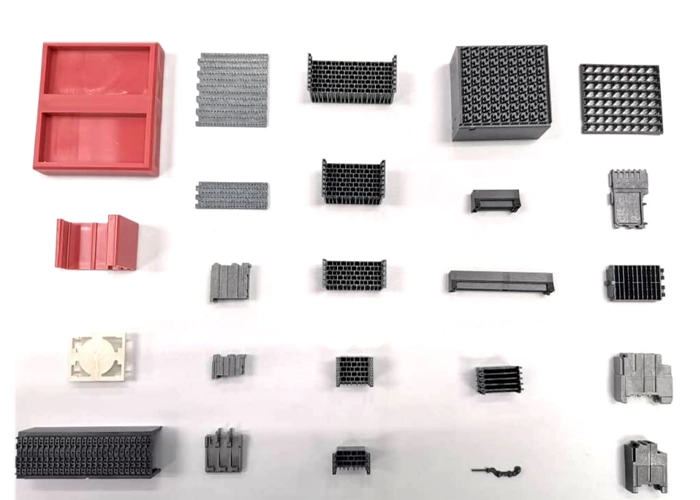

We launched a 100k cleanroom for injection molding and began mass production of customized heatsinks, reinforcing our position as a forward-thinking, high-precision manufacturer.

At Precede Group of Companies, we pride ourselves on our extensive expertise in delivering high-quality, custom-engineered solutions across various industries. With over two decades of experience, our team is dedicated to providing precision in every aspect of our work.

We provide end-to-end solutions in injection molding, and ensuring top-quality and reliable performance for industries worldwide.

Our customized jigs and fixtures ensure precise alignment and robust support, streamlining assembly and testing processes for maximum efficiency.

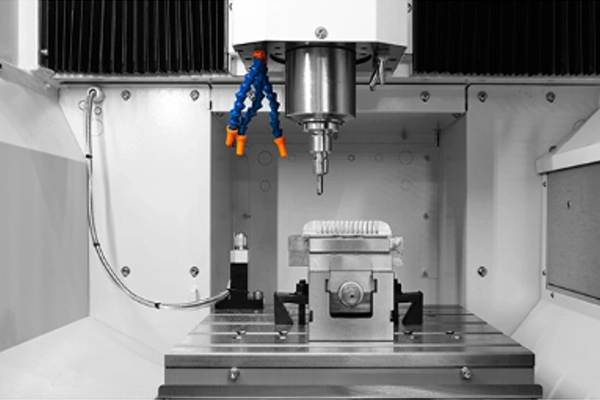

Our precision tooling solutions deliver high-accuracy molds and dies designed to optimize manufacturing performance.

Our injection molding services utilize advanced technology to produce cleanroom-grade components with exceptional consistency and quality.

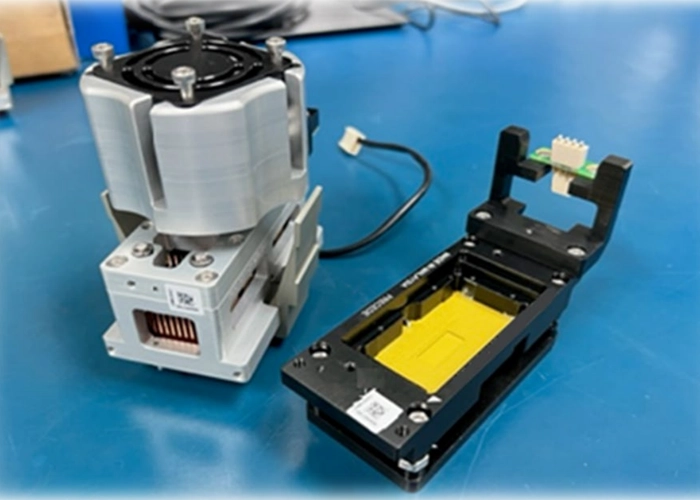

Our test sockets provide reliable connectivity and and accuracy for semiconductor testing, meeting stringent industry requirements.

Our retention hardware is engineered to secure critical assemblies in high-stress environments, ensuring stability, durability, and performance under extreme conditions.

At Precede Group, we combine state-of-the-art engineering with innovative technology to deliver unmatched precision and quality. Our integrated production systems and rigorous quality controls ensure components meet the highest industry standards and quality. Explore how our integrated machinery and rigorous quality controls enable us to manufacture components that meet the highest industry standards.

We leverage advanced CNC, EDM, and wire-cutting machinery from top brands to produce high-precision components with exceptional accuracy.

Our injection molding floor is equipped with dehumidifier dryers, automated robotic arms, and vision inspection systems, ensuring cleanroom-grade production and consistent quality.

Our cutting-edge inspection equipment, including CMMs, digital calipers, and profile projectors, guarantees every product adheres to strict precision standards.

At Precede Group of Companies, we utilise state-of-the-art high-precision machinery to meet the demanding needs of the semiconductor, automotive, and telecommunication industries.

We operate high-speed, high-accuracy machines to ensure superior fabrication and metalwork quality:

Our CAD/CAM software ensures greater design flexibility, better production control, and increased product quality.

To maintain precision up to one ten-thousandth of an inch, we use a rigorous testing process with advanced measurement equipment:

We are ISO 9001:2000 certified, ensuring strict quality control, frequent equipment calibration, and consistent reliability in our manufacturing processes.

Delivering precision, reliability, and efficiency with cutting-edge technology and expert craftsmanship.

With over 30 years of experience, we have built a reputation as a trusted provider of precision tooling, injection molding, and automation solutions.

We adhere to the highest international quality standards, holding ISO 9001:2015, UL, and RoHS certifications to ensure compliance, safety, and reliability in all our products.

Our facilities are equipped with the latest CNC machining, EDM, wire cut, and injection molding technology, including a 100K cleanroom for contamination-free production.

We understand that every industry has unique requirements. Our team works closely with clients to develop tailored solutions that enhance performance and efficiency.

From low-volume prototypes to high-volume manufacturing, we ensure consistent quality, fast turnaround times, and cost-effective solutions for all production scales.

At Precede Group, we provide cutting-edge precision tooling, engineering and injection molding solutions to support industries that demand high accuracy, reliability, and efficiency. With decades of experience and ISO 9001:2015, UL, and RoHS certifications, we serve a wide range of industries with customized, high-performance components that meet stringent industry requirements.

We specialise in high-precision tooling and injection molding for semiconductor manufacturing, producing essential components such as:

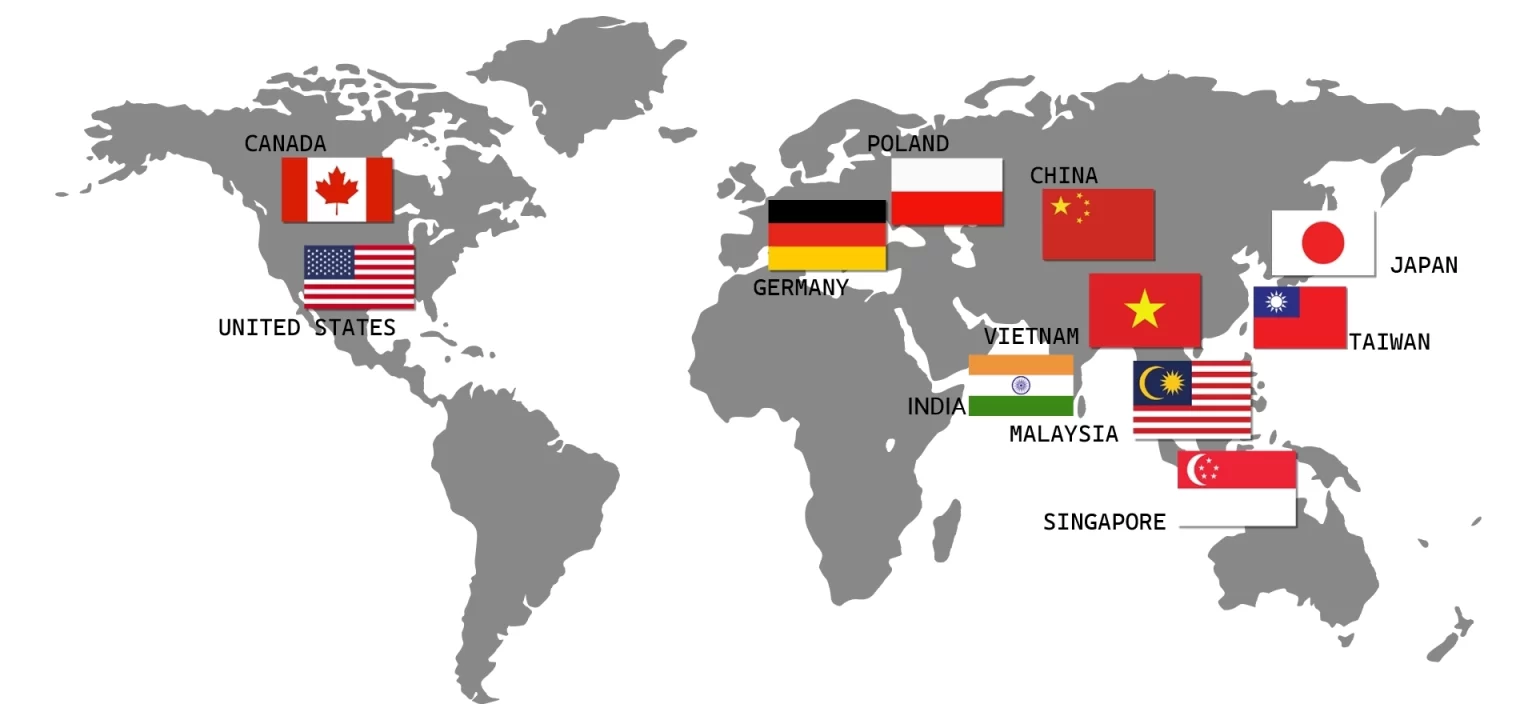

We support global clients from different markets with high quality of products and solutions trusted worldwide.

Have a question or need a customised precision engineering solution?

Fill in the form below, and we’ll get back to you soon.